Hot Stamping Machines

Hot stamping is a dry process that applies a foil or multi-colored foil image by using a hot die and a sheet of stamping foil or film. Hot stamping uses either a single-colored foil to apply a shiny metallic print or a pre-printed heat transfer to apply multiple colors at one time. Read More…

Is your facility in need of high performance dot peen machines? Our top of the line machinery is guaranteed to meet all of your needs. We are your worry-free provider of identification systems. We will work with your team to implement our products into your business and our services are beyond compare. Our company has proven ourselves as an industry leader!

Laser Marking Technologies LLC has served the marking machinery and laser cutting services industries for over 20 years. Our years of experience and advanced technology make us a leader in marking machinery and laser-cutting services.

At Automark, our team of experts is ready and willing to tackle any of your challenging assignments. We supply marking systems for a multitude of industries such as medical, cosmetic, industrial, automotive, and more. All of our machines are manufactured to the highest quality, offered at a competitive price, and are guaranteed to last. Give us a call and a representative will speak with you...

A world market leader in the field of marking machinery, Alpine Metal Tech is a “full-liner” for all marking & reading technologies throughout the process chain in every sector of the marking machinery industry. We offer products such as laser marking equipment, marking systems, hot stamping machines, marking tools & embossing machines. Customers come first with our company. Contact us to...

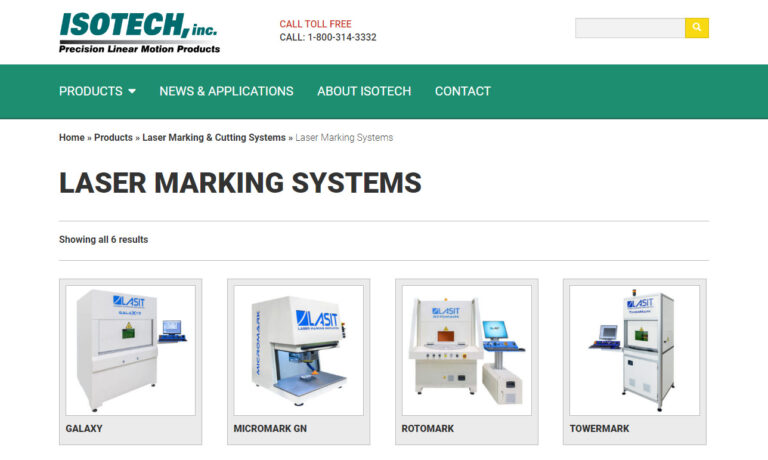

Isotech offers a full range of Fiber, C02, UV, Green, MOPA, Nanosecond, Picosecond and Femtosecond laser systems for marking, cutting and welding of many substrates. Isotech offers both standard systems as well as fully automated or custom systems depending on your specific requirements. Integrated, automated solutions with conveyors, palletized pick and place, rotary dial tables, hoppers, and...

More Hot Stamping Machine Manufacturers

Hot stamping is a thermal bonding process and achieves permanent adherence between the surface material and the foil, and the resulting image can withstand some harsh conditions while remaining legible, making it an ideal process for the purposes of product identification. The marking tools used include a die, or sculpted metal design, which is used in the process of hot-stamping and is typically made form a metals such as copper, brass or steel. The die is heated and then pressed down on a piece of foil above the material being stamped.

The heat causes the foil to adhere to the material's surface in the pattern or image of the die. The quality of the stamped image depends on a number of factors - the heat of the die and the length of time the stamp is used for, as well as the amount of pressure applied all affect the image. Material compatibility also needs to be considered.

The process of hot stamping cannot be used with some materials that cannot maintain their properties under the heat and pressure of a stamping die. Other materials may be resistant to adhering to the foil stamp and therefore hot stamping would be ineffective. It is important to adequately support the material being marked, hot stamping requires a great amount of pressure and the consistency with which it is applied to a surface will affect the quality of the finished product.

Industries which utilize the part marking process of hot stamping include aerospace, automotive, biotech, cable and electrical and construction. Items such as HVAC systems, control panels, microwaves and semi-conductors use foil stamping in one form or another, as do common consumer applications such as greeting card and book covers, award ribbons, phone cards, poker chips, and many other products. Hot stamping is clean, fast, and dry and uses no inks or solvents, allowing it to be recognized as a sustainable and environmentally friendly procedure.

Furthermore, no knowledge of chemicals is required as there are none used in the marking process. There are no gases or fumes emitted from the labeling or stamping, and apart from the heat required to heat up the die and power the stamping press, there is little energy consumed by stamping. The three major types of hot stamping are vertical stamping, roll-on, and peripheral decorating.

Vertical stamping applies stamp foil or heat transfers to a flat area or up to 90 degrees of a cylindrical area. Roll-on hot stamping works best for flat, large-area surfaces. Peripheral decorating, in comparison, is used to decorate the perimeter of a part, up to 360 degrees.

Cardboard Tubes

Cardboard Tubes Carrying Cases

Carrying Cases Contract Packaging

Contract Packaging Corrugated Boxes

Corrugated Boxes Dot Peening Machines

Dot Peening Machines Labeling Machinery

Labeling Machinery Marking Machinery

Marking Machinery Packaging Equipment

Packaging Equipment Palletizers

Palletizers Plastic Bags

Plastic Bags Sewing Contractors

Sewing Contractors Tape Suppliers

Tape Suppliers Castings & Forgings

Castings & Forgings Bulk Material Handling

Bulk Material Handling Electrical & Electronic Components

Electrical & Electronic Components Flow Instrumentation

Flow Instrumentation Hardware

Hardware Material Handling Equipment

Material Handling Equipment Metal Cutting Services

Metal Cutting Services Metal Forming Services

Metal Forming Services Metal Suppliers

Metal Suppliers Motion Control Products

Motion Control Products Plant & Facility Equipment

Plant & Facility Equipment Plant & Facility Supplies

Plant & Facility Supplies Plastic Molding Processes

Plastic Molding Processes Pumps & Valves

Pumps & Valves Recycling Equipment

Recycling Equipment Rubber Products & Services

Rubber Products & Services