To cover the wide spectrum of industries utilizing marking systems and the vast variety of products that are affected by the process, a specific material may be focused on to narrow the field. Metal is the perfect material to focus on because it is utilized in so many of the industries that use marking systems. Also, because the softness level of metals varies and heat can make them more malleable, metals are able to be marked by almost every type of marking machine on the market today.

The automotive manufacturing industry uses multiple marking systems during their production of car parts and integration of the whole vehicle system. For environmental reasons, the lighter-weight aluminum is now the most common metal utilized in vehicles, more so then the heavy-duty iron and steel of the past. Laser markers are used to etch code numbers into specific aluminum parts during production to enable the manufacturer to keep track of each item in the system and ensure that the vehicle is fully developed and put together correctly. Another couple metals often marked by lasers are titanium and stainless steel in the medical field, which are both sanitary metals used for surgeries and such and require tracking through the hospital system.

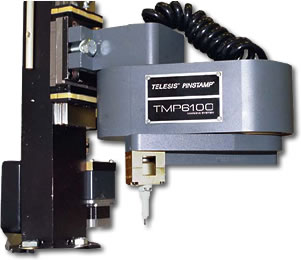

Engraving marking systems use knives attached to CNC machining equipment to create clean and precise grooves into metal much like laser markers. Machines used in manufacturing and construction, such as lifting clamps, snatch blocks, parts washer and the identification tags attached to every piece of machinery are always made of metal that must be marked. Chrome, steel, cast iron and various alloys are used for these machines, depending on the purpose they serve. Embossing machines, hot stamping machines and dot peen machines are all different techniques used to permanently mark these industrial sized products with id numbers, instructions and logos.

Cardboard Tubes

Cardboard Tubes Carrying Cases

Carrying Cases Contract Packaging

Contract Packaging Corrugated Boxes

Corrugated Boxes Dot Peening Machines

Dot Peening Machines Labeling Machinery

Labeling Machinery Marking Machinery

Marking Machinery Packaging Equipment

Packaging Equipment Palletizers

Palletizers Plastic Bags

Plastic Bags Sewing Contractors

Sewing Contractors Tape Suppliers

Tape Suppliers Castings & Forgings

Castings & Forgings Bulk Material Handling

Bulk Material Handling Electrical & Electronic Components

Electrical & Electronic Components Flow Instrumentation

Flow Instrumentation Hardware

Hardware Material Handling Equipment

Material Handling Equipment Metal Cutting Services

Metal Cutting Services Metal Forming Services

Metal Forming Services Metal Suppliers

Metal Suppliers Motion Control Products

Motion Control Products Plant & Facility Equipment

Plant & Facility Equipment Plant & Facility Supplies

Plant & Facility Supplies Plastic Molding Processes

Plastic Molding Processes Pumps & Valves

Pumps & Valves Recycling Equipment

Recycling Equipment Rubber Products & Services

Rubber Products & Services