Product trackability, brand protection, and numerous information labels are all included in the broad area of labeling known as “product identification.” Product identity labeling is essential because of the constantly shifting business environment and threats from theft and fake goods. Read More…

Epilog Laser specializes in laser marking systems, CO2 lasers, diode lasers, laser cutting machines & systems for laser engraving like tabletop engravers, mid-sized engravers & large-format engraving systems. We have offered laser technology since 1988 and are the leader in CO2 & fiber laser systems.

Is your facility in need of high performance dot peen machines? Our top of the line machinery is guaranteed to meet all of your needs. We are your worry-free provider of identification systems. We will work with your team to implement our products into your business and our services are beyond compare. Our company has proven ourselves as an industry leader!

Laser Marking Technologies LLC has served the marking machinery and laser cutting services industries for over 20 years. Our years of experience and advanced technology make us a leader in marking machinery and laser-cutting services.

At Automark, our team of experts is ready and willing to tackle any of your challenging assignments. We supply marking systems for a multitude of industries such as medical, cosmetic, industrial, automotive, and more. All of our machines are manufactured to the highest quality, offered at a competitive price, and are guaranteed to last. Give us a call and a representative will speak with you...

Isotech offers a full range of Fiber, C02, UV, Green, MOPA, Nanosecond, Picosecond and Femtosecond laser systems for marking, cutting and welding of many substrates. Isotech offers both standard systems as well as fully automated or custom systems depending on your specific requirements. Integrated, automated solutions with conveyors, palletized pick and place, rotary dial tables, hoppers, and...

More Product Identification Manufacturers

Product Labeling for Traceability of Products

Product traceability is a critical component in today’s global supply chain, manufacturing, and distribution environments. The ability to track and trace a product from its origin—covering raw material sourcing, manufacturing, packaging, distribution, and delivery to the final consumer—enables businesses to maintain quality control, ensure regulatory compliance, and swiftly address recalls or quality issues. This end-to-end visibility is essential across industries such as automotive, electronics, pharmaceuticals, food and beverage, aerospace, medical devices, and consumer goods.

What is Product Traceability? The capacity to follow a product from its conception through production, assembly, distribution, and ultimately to the end-user is known as product traceability. In an ideal traceability system, companies can identify the origin of every component or ingredient, track the journey through each production stage, and monitor the product’s lifecycle even after it has reached the customer. This level of transparency is vital for quality assurance, regulatory compliance, sustainability initiatives, and brand protection.

Why is Product Traceability Important? Implementing robust traceability practices helps organizations respond quickly to product recalls, minimize the impact of quality control issues, and demonstrate compliance with increasingly stringent government regulations and industry standards (such as FDA, ISO 9001, or GS1). It also reassures customers about product authenticity and safety, supporting brand reputation and consumer trust.

To enable effective traceability, product identification labels—often incorporating unique identifiers such as serial numbers, batch or lot codes, and barcodes—are required. These labels allow for accurate tracking throughout the supply chain, making it possible to quickly isolate affected products if a recall or defect is detected. Several advanced labeling technologies and marking systems are available to support traceability objectives.

How Do Product Identification Labels Work?

Product identification labels serve as the backbone of traceability programs. These labels can be affixed to products, components, or packaging and typically include critical data such as:

- Serial numbers

- Batch or lot codes

- Barcodes (1D and 2D, including QR codes and Data Matrix codes)

- Production and expiration dates

- Manufacturer information

- Regulatory compliance marks

These identifiers enable automated tracking using barcode scanners or RFID readers, facilitate digital record-keeping, and provide instant access to product history. The choice of labeling method and materials depends on the product’s use case, environmental conditions, regulatory requirements, and the desired level of security.

Key Applications of Product Traceability Labels

Product traceability and identification labeling are crucial for:

- Recall Management: Quickly locating and removing non-compliant or defective products from the marketplace.

- Anti-counterfeiting: Protecting brands by authenticating genuine products and preventing fraud.

- Supply Chain Optimization: Enhancing visibility, efficiency, and inventory control through real-time product tracking.

- Regulatory Compliance: Meeting legal requirements for labeling, tracking, and reporting (e.g., FDA UDI, EU MDR, FSMA, REACH).

- Consumer Engagement: Enabling transparency for customers interested in product origin, sustainability, or ethical sourcing.

Advanced Labeling Technologies for Traceability

A variety of cutting-edge labeling and marking technologies are available to meet diverse traceability needs, including:

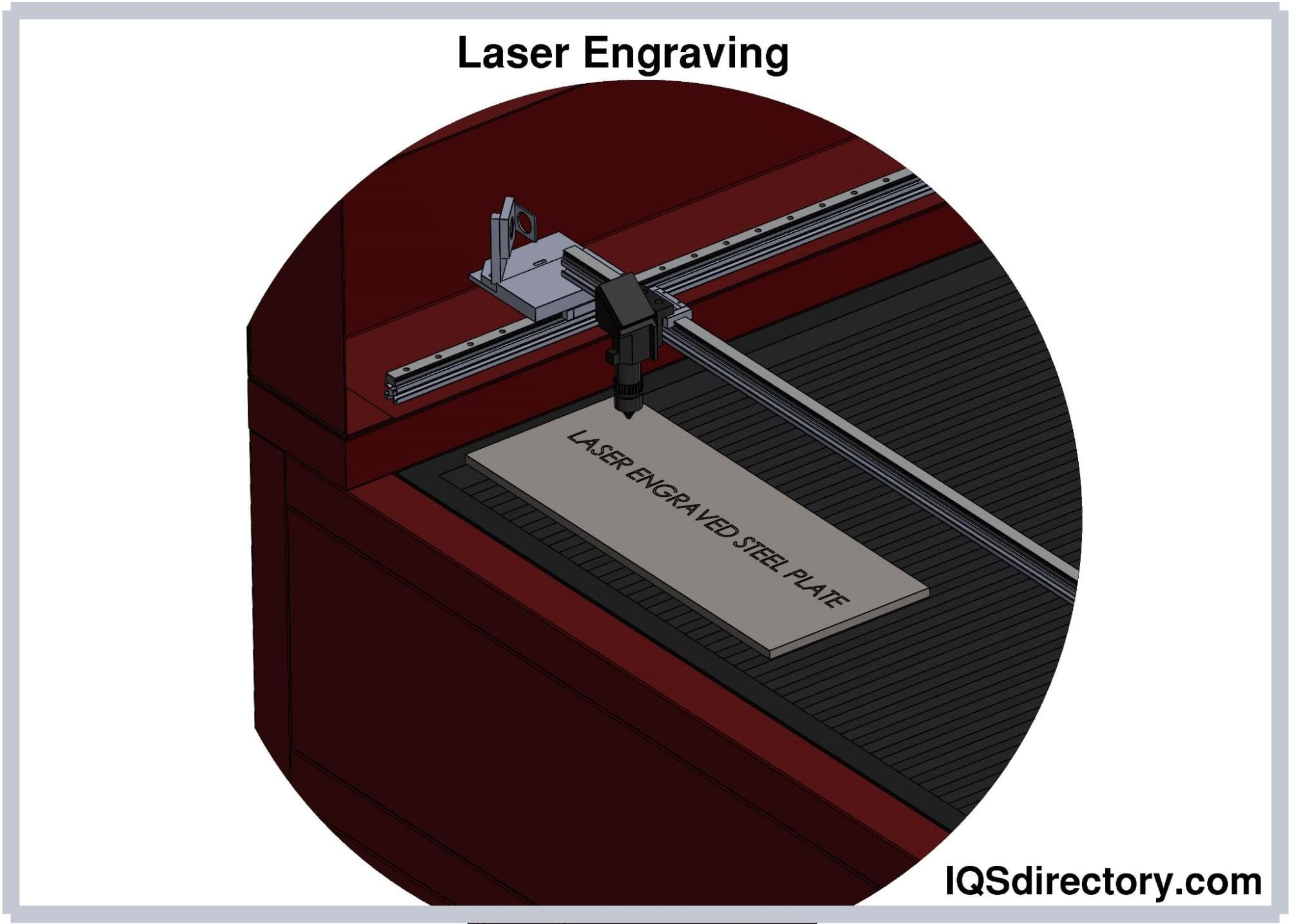

1. Laser Marking

Laser marking for product identification is a highly effective and versatile method for applying permanent, high-resolution marks—including part numbers, barcodes, serialization, lot codes, and logos—to a wide array of materials such as metals, plastics, glass, and ceramics. The laser marking process is favored in industries requiring durable, tamper-evident, and legible markings that withstand harsh environments.

Key benefits of laser marking for traceability:

- Permanence: Laser marks are highly resistant to abrasion, chemicals, heat, and UV exposure, making them ideal for automotive, aerospace, medical device, and electronics labeling.

- Non-contact process: No physical contact with the material eliminates the risk of mechanical stress or deformation, which is especially important for delicate or sensitive components.

- Eco-friendly and cost-efficient: Laser marking does not use inks, solvents, or consumables, reducing operating costs and environmental impact.

- Versatility: Mark a wide range of substrates by adjusting laser power and speed. Surface modifications (such as color changes or annealing) prevent bacteria accumulation—vital for food, pharmaceutical, and healthcare applications.

- Customization: Easily implement variable data (serial numbers, barcodes, lot codes, graphics) for full traceability and anti-counterfeiting.

Other marking methods, such as inkjet, dot peen, and chemical etching, are alternatives; however, they often require consumables and may lack the permanence, precision, or speed of laser marking. Still, these alternate methods can be suitable for certain use cases or budget constraints.

Frequently Asked Questions: Laser Marking for Product Traceability

- What materials can be marked with a laser marking system? Metals (steel, aluminum, titanium), plastics, glass, ceramics, composites, and coated surfaces can all be marked with the proper laser configuration.

- How does laser marking compare to inkjet marking for high-volume manufacturing? Laser marking offers higher durability and lower total cost of ownership for many applications, especially where long-lasting or tamper-proof identification is critical.

- Is laser marking suitable for food and medical packaging? Yes. Laser marking can provide hygienic, non-contact, and residue-free marks, meeting FDA and EU food safety requirements.

2. Watermark Using UV

Ultraviolet (UV) watermarks are a specialty labeling solution designed to enhance product security and deter counterfeiting. UV watermarks are invisible to the naked eye but become visible under UV light, making them an effective tool for authenticating genuine products and preventing unauthorized duplication.

Applications of UV watermark labels:

- Pharmaceutical packaging to comply with anti-counterfeiting regulations

- Luxury goods and high-value electronics authentication

- Event ticketing and document security

- Brand protection for cosmetics, spirits, and consumer goods

These UV watermarks can be seamlessly integrated with other labeling technologies, such as QR codes or serialized barcodes, to provide a multi-layered security approach.

3. Variable Information Labels

Variable information labels (VILs), also known as variable data labels, allow manufacturers and distributors to print unique and dynamic data on each label—such as lot numbers, batch codes, expiration dates, and manufacturing details. This capability is essential for compliance, recall readiness, and customer engagement, especially in regulated or high-mix manufacturing environments.

Features and benefits of variable information labeling:

- Customizable data fields: Print text, numbers, barcodes, QR codes, graphics, or even RFID chips for real-time tracking.

- On-demand printing: Industrial label printers and print-and-apply systems allow for instant, flexible label generation on the production line.

- Enhanced traceability: Supports unique identification and rapid recall processes for pharmaceuticals, food and beverage, electronics, and automotive industries.

- Supports compliance: Helps meet international standards such as GS1, ISO, and FDA UDI requirements.

In scenarios where handwritten data must be added securely to a label, Embossable Poly Tape provides a tamper-evident solution. Information embossed into the tape cannot be altered or erased, further supporting traceability and security.

Common use cases for VILs: Medical device labeling, packaging for perishable goods, electronic component tracking, industrial batch control, and warranty management.

Did you know? Variable information labels can also serve as brand reputation labels, providing consumers with transparency into product origin, ethical sourcing, and environmental impact.

Labeling Durable Goods and Industrial Products

Labeling for durable goods—such as industrial machinery, tools, appliances, electronic equipment, and vehicles—requires labels that can withstand harsh conditions, including exposure to chemicals, moisture, abrasion, extreme temperatures, and UV light. These labels are often referred to as nameplates and must remain legible throughout the product’s lifespan.

Specialty label materials and adhesives for durable goods:

- Metalized poly tapes: Provide a premium, brushed-metal appearance while being lightweight and easy to produce. Ideal for branding and compliance marking on appliances, equipment, and electronics.

- Ultra-aggressive adhesive labels: Designed for challenging substrates such as leather, textiles, powder-coated metals, and rough or uneven surfaces. These industrial-strength adhesives ensure long-term adhesion, even in difficult environments.

- Chemical-resistant tapes: Essential for labeling products exposed to wash-downs, solvents, or cleaning agents—common in food processing, pharmaceutical, and chemical manufacturing plants.

- High-temperature polyimide tapes: Used for circuit boards and electrical components, polyimide labels offer high dielectric strength and thermal resistance (from -40°F to 356°F), making them suitable for electronics, automotive, and aerospace applications.

Industry use cases for durable labeling:

- Compliance and safety labeling for industrial machinery and electrical panels

- Asset tracking and inventory management in warehouses and logistics

- Product branding for appliances, power tools, and consumer electronics

- Maintenance and service records for equipment and vehicles

- Component identification for aerospace and automotive assemblies

How to Select the Right Label Material and Adhesive?

Choosing the correct label material and adhesive is crucial for long-term traceability and regulatory compliance. Factors to consider include:

- Surface type and texture: Smooth, rough, curved, or challenging substrates may require specific adhesives.

- Environmental exposure: Consider heat, humidity, UV, chemicals, abrasion, and cleaning processes.

- Product lifecycle: Labels may need to last for the product’s entire service life or only until delivery.

- Industry-specific requirements: Check for regulatory standards (e.g., UL, CSA, RoHS, REACH, FDA) relevant to your market.

- Print technology compatibility: Ensure the label material supports the chosen marking method (laser, inkjet, thermal transfer, etc.).

Need help selecting the right labeling solution? Contact our experts or request a sample to evaluate performance in your unique application.

Emerging Trends and Innovations in Product Traceability Labeling

As global supply chains become more complex and regulatory expectations rise, new trends are shaping the future of product labeling and traceability. Staying ahead of these trends can help businesses maintain compliance, enhance operational efficiency, and deliver greater value to customers.

Key innovations include:

- RFID-enabled labels: Radio-frequency identification (RFID) tags allow for contactless, real-time tracking of products throughout the supply chain. RFID labeling is increasingly used in retail, logistics, automotive, and healthcare to automate inventory management and theft prevention.

- Smart labels and IoT integration: Incorporating NFC chips, Bluetooth sensors, or QR codes enables interactive labels that connect products to digital experiences, providing traceability data, usage instructions, or reordering options via smartphones and tablets.

- Blockchain for secure traceability: Blockchain technology ensures immutable, transparent records of product provenance, supporting anti-counterfeiting, compliance, and sustainability claims.

- Sustainable label materials: Eco-friendly options such as recycled content, biodegradable adhesives, and water-based inks help reduce environmental impact and meet green packaging mandates.

- Cloud-based traceability software: Advanced labeling systems now integrate with ERP, MES, and WMS platforms for centralized data management, analytics, and compliance reporting.

Common Questions About Product Traceability Labels

- What is the difference between a barcode label and an RFID label? Barcode labels are optically scanned, while RFID labels are read via radio waves and do not require line-of-sight.

- How do I ensure my labels comply with global regulations? Work with a labeling partner experienced in your industry’s standards and test label materials for durability and legibility.

- Can traceability labels be customized for my branding? Yes. Modern labeling systems support full-color graphics, logos, and variable data for cohesive branding and messaging.

- What are the best practices for managing traceability data? Use centralized, cloud-based software to store, analyze, and report on label data, and ensure integration with your supply chain systems.

How to Choose the Correct Product Identification Company

Selecting the right product identification company or traceability solution provider is essential for achieving compliance, reliability, and scalability in your labeling operations. Here’s a step-by-step approach to making an informed decision:

- Define your requirements: Assess your product types, industry regulations, environmental challenges, and traceability goals.

- Research providers: Use our directory of product identification businesses to compare labeling companies with expertise in your field. Each company profile includes details on their capabilities, certifications, and industry experience.

- Evaluate technologies: Review each provider’s marking methods (laser, inkjet, RFID, etc.), label material options, and software integrations. Check if they offer turnkey solutions for your unique applications.

- Request samples and demos: Test label performance in real-world conditions. Ask for case studies or references from similar industries.

- Request quotes and proposals: Use our RFQ form to contact multiple companies and compare pricing, lead times, and support services.

- Prioritize customer support and training: Ensure your labeling partner provides comprehensive technical support, user training, and resources for ongoing compliance.

Want to streamline your selection process? Explore our proprietary website previewer to quickly evaluate product identification companies and find the best fit for your needs.

Conclusion: The Value of Effective Product Traceability Labeling

Implementing a robust product labeling and traceability system is no longer optional—it is a competitive necessity in today’s global, quality-driven marketplace. Whether you’re in manufacturing, logistics, healthcare, electronics, or consumer goods, traceability labels ensure product integrity, regulatory compliance, supply chain efficiency, and brand trust.

By leveraging advanced marking technologies (such as laser marking, UV watermarking, RFID, and variable information labels), selecting the right materials and adhesives for your environment, and partnering with experienced labeling companies, you can future-proof your traceability program and deliver value to your customers.

Ready to take the next step? Contact our traceability experts or request a quote to discover how our product identification solutions can help you achieve your business goals.

Cardboard Tubes

Cardboard Tubes Carrying Cases

Carrying Cases Contract Packaging

Contract Packaging Corrugated Boxes

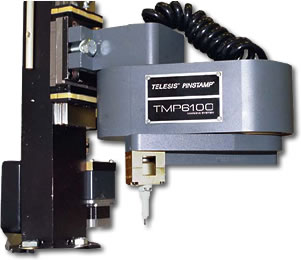

Corrugated Boxes Dot Peening Machines

Dot Peening Machines Labeling Machinery

Labeling Machinery Marking Machinery

Marking Machinery Packaging Equipment

Packaging Equipment Palletizers

Palletizers Plastic Bags

Plastic Bags Sewing Contractors

Sewing Contractors Tape Suppliers

Tape Suppliers Castings & Forgings

Castings & Forgings Bulk Material Handling

Bulk Material Handling Electrical & Electronic Components

Electrical & Electronic Components Flow Instrumentation

Flow Instrumentation Hardware

Hardware Material Handling Equipment

Material Handling Equipment Metal Cutting Services

Metal Cutting Services Metal Forming Services

Metal Forming Services Metal Suppliers

Metal Suppliers Motion Control Products

Motion Control Products Plant & Facility Equipment

Plant & Facility Equipment Plant & Facility Supplies

Plant & Facility Supplies Plastic Molding Processes

Plastic Molding Processes Pumps & Valves

Pumps & Valves Recycling Equipment

Recycling Equipment Rubber Products & Services

Rubber Products & Services