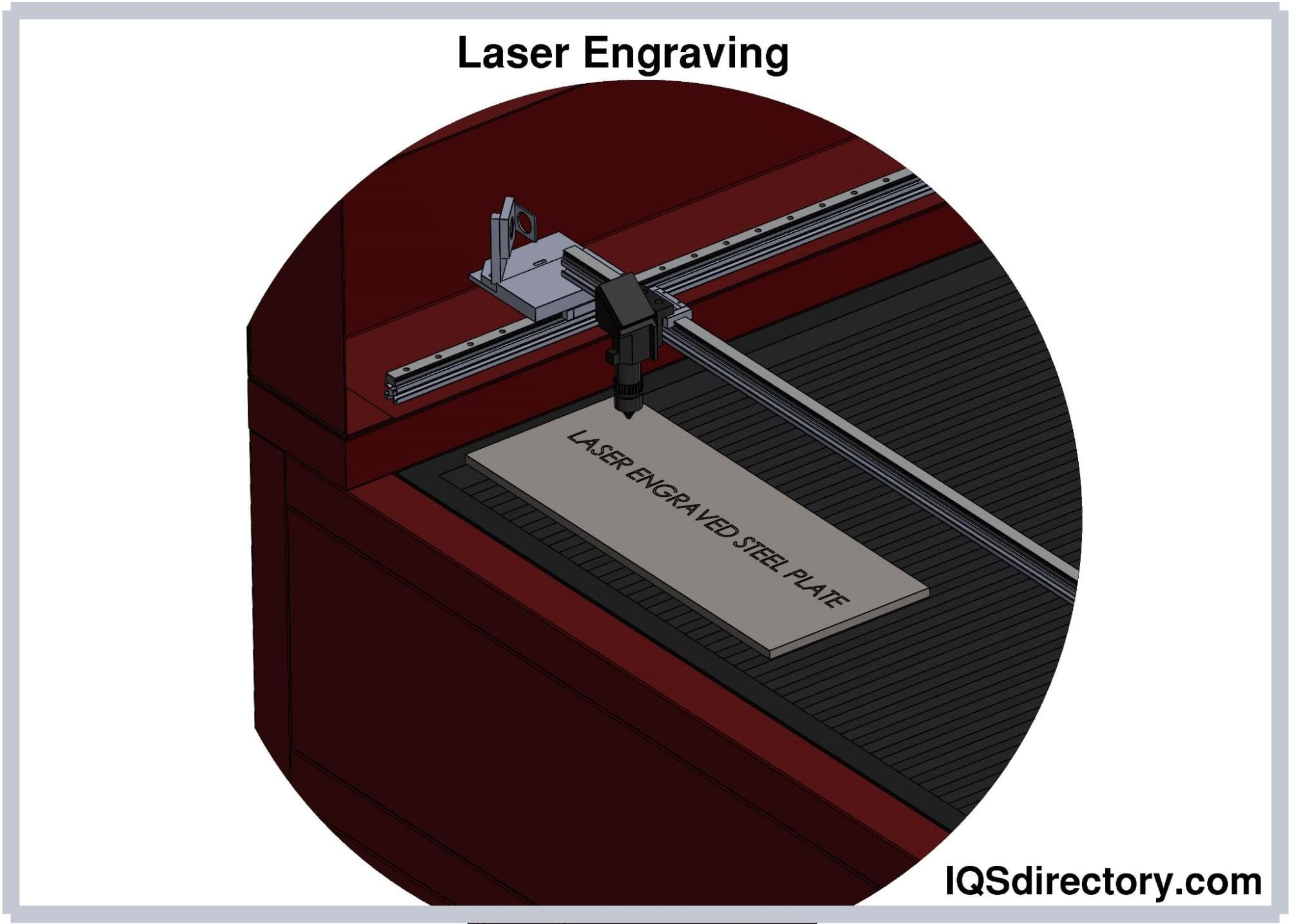

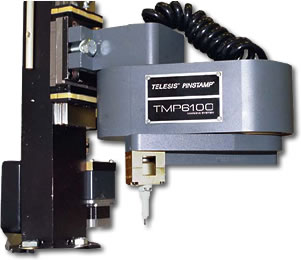

Part marking uses a broad range of machinery and techniques including: dot peen machines which utilize an impact method of marking leaving an impression on the surface, laser markers which use laser radiation to mark parts, and embossing and engraving machines for more traditional methods of part marking. Read More…

Epilog Laser specializes in laser marking systems, CO2 lasers, diode lasers, laser cutting machines & systems for laser engraving like tabletop engravers, mid-sized engravers & large-format engraving systems. We have offered laser technology since 1988 and are the leader in CO2 & fiber laser systems.

Is your facility in need of high performance dot peen machines? Our top of the line machinery is guaranteed to meet all of your needs. We are your worry-free provider of identification systems. We will work with your team to implement our products into your business and our services are beyond compare. Our company has proven ourselves as an industry leader!

Laser Marking Technologies LLC has served the marking machinery and laser cutting services industries for over 20 years. Our years of experience and advanced technology make us a leader in marking machinery and laser-cutting services.

At Automark, our team of experts is ready and willing to tackle any of your challenging assignments. We supply marking systems for a multitude of industries such as medical, cosmetic, industrial, automotive, and more. All of our machines are manufactured to the highest quality, offered at a competitive price, and are guaranteed to last. Give us a call and a representative will speak with you...

Isotech offers a full range of Fiber, C02, UV, Green, MOPA, Nanosecond, Picosecond and Femtosecond laser systems for marking, cutting and welding of many substrates. Isotech offers both standard systems as well as fully automated or custom systems depending on your specific requirements. Integrated, automated solutions with conveyors, palletized pick and place, rotary dial tables, hoppers, and...

More Part Marking Manufacturers

Product indentification marks are becoming increasingly important in the industrial world for a number of reasons. Firstly, part marking allows businesses to reduce counterfeiting by utilizing product identification, and by checking manufacturer's identification codes or seals. Furthermore, the process of traceability and ensuring the accountability of the manufacturer is becoming increasingly necessary for both local and export purposes. Today, most businesses in the automotive, medical and aerospace industries will refuse to consider purchasing inadequately marked products from suppliers.

Another reason for part marking is that customer recognition grows due to the increased visibility of a company's logo or design on its product components. Part marking is also able to assign value to products, for example jewelry, that can have a wide range of values without an easily noticeable physical difference. This process is becoming more common and many everyday products, like promotional gifts, plaques or engine parts, are now typically identified by marking machines.

The most common marking material is metal, but part marking machinery is able to mark other materials such as paper, plastic, wood, leather, glass, fabric and textiles. Credit cards, jewelry, writing utensils, packaging, greeting cards, wood trim and glass sculptures represent the wide range of materials on which marking machinery systems are used. Non-intrusive methods of part marking are necessary for parts used in safety and critical applications such as aircraft or medical equipment.

Dot peen marking or embossing may not be the wisest part marking method of choice because of the disruption caused to the surface of the product. Other choices to consider include the reasons for the part - if for commercial purposes, it is important that the code or logo or design be easily visible to the consumer. If the mark is for authenticity or verification purposes however, it does not need to be easily visible, and tends to be in a discreet place.

The permanency of the part identification mark tends to depend on the intended life span of the product and the context of its use, and this will be a factor in determining which process to use when marking the part.

Cardboard Tubes

Cardboard Tubes Carrying Cases

Carrying Cases Contract Packaging

Contract Packaging Corrugated Boxes

Corrugated Boxes Dot Peening Machines

Dot Peening Machines Labeling Machinery

Labeling Machinery Marking Machinery

Marking Machinery Packaging Equipment

Packaging Equipment Palletizers

Palletizers Plastic Bags

Plastic Bags Sewing Contractors

Sewing Contractors Tape Suppliers

Tape Suppliers Castings & Forgings

Castings & Forgings Bulk Material Handling

Bulk Material Handling Electrical & Electronic Components

Electrical & Electronic Components Flow Instrumentation

Flow Instrumentation Hardware

Hardware Material Handling Equipment

Material Handling Equipment Metal Cutting Services

Metal Cutting Services Metal Forming Services

Metal Forming Services Metal Suppliers

Metal Suppliers Motion Control Products

Motion Control Products Plant & Facility Equipment

Plant & Facility Equipment Plant & Facility Supplies

Plant & Facility Supplies Plastic Molding Processes

Plastic Molding Processes Pumps & Valves

Pumps & Valves Recycling Equipment

Recycling Equipment Rubber Products & Services

Rubber Products & Services