Inkjet printers are an important part of manufacturing as a method for printing identifying marks, data, and part numbers on products. The wide use of inkjet printers is due to the non-contact printing process that prints sharp, clear, accurate, and legible words, numbers and images quickly and efficiently. Read More…

Epilog Laser specializes in laser marking systems, CO2 lasers, diode lasers, laser cutting machines & systems for laser engraving like tabletop engravers, mid-sized engravers & large-format engraving systems. We have offered laser technology since 1988 and are the leader in CO2 & fiber laser systems.

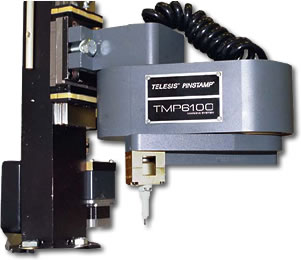

Is your facility in need of high performance dot peen machines? Our top of the line machinery is guaranteed to meet all of your needs. We are your worry-free provider of identification systems. We will work with your team to implement our products into your business and our services are beyond compare. Our company has proven ourselves as an industry leader!

Laser Marking Technologies LLC has served the marking machinery and laser cutting services industries for over 20 years. Our years of experience and advanced technology make us a leader in marking machinery and laser-cutting services.

At Automark, our team of experts is ready and willing to tackle any of your challenging assignments. We supply marking systems for a multitude of industries such as medical, cosmetic, industrial, automotive, and more. All of our machines are manufactured to the highest quality, offered at a competitive price, and are guaranteed to last. Give us a call and a representative will speak with you...

Isotech offers a full range of Fiber, C02, UV, Green, MOPA, Nanosecond, Picosecond and Femtosecond laser systems for marking, cutting and welding of many substrates. Isotech offers both standard systems as well as fully automated or custom systems depending on your specific requirements. Integrated, automated solutions with conveyors, palletized pick and place, rotary dial tables, hoppers, and...

More Inkjet Printer Manufacturers

The quick printing provided by inkjet printers make them ideal for labeling products and packaging materials during production and assembly. The versatility of inkjet printers makes it possible to include them in any form of automation and robotic functions.

The inkjet printing process is unlike traditional printing that requires contact with an item during the printing process. What differentiates inkjet printing from other forms of printing is the spraying of small droplets of ink onto a substrate to produce images and text. The spray method is a controlled application that makes it possible to produce clear and concise images quickly and efficiently.

Inkjet Printing

Inkjet printers are capable of printing any type of information on any surface, regardless of the texture and consistency of a surface. This aspect of the inkjet process gives it a great deal of advantage over other printing methods. Each industry requires different types of information placed on their products.

The variations in information that is printed by industrial inkjet printers range from simple part numbers to details for advertising a product or directions for installing a product. The basic information that is necessary for industrial use includes lot codes, date codes, batch numbers, product information, and, in recent years, bar codes and electronic information. This use of inkjet printers is necessitated by the need for products to carry information for improved performance and product protection.

Barcodes

One of the technological revelations of modern manufacturing has been the advent of barcodes that supply a wide range of information in a simple symbol. Inkjet printers are the quickest and easiest method for placing barcodes on products. Direct part marking (DPM) places barcodes in the required location eliminating the need to print separate labels. In addition, inkjet printed barcodes are more permanent than labels since it would require a great deal of effort to remove them from the surface of products.

Date Codes

The purpose of date codes is to indicate the date that a product is produced. This is especially important for time sensitive items that can lose their value if not sold or used during a specified period of time. In grocery stores, inkjet printers are used daily to produce labels that are applied to fruits and vegetables to indicate when a food product should be removed from the shelves. The use of inkjet printers in the food industry is due to their speed and accuracy since date codes have to be printed every day.

Product Information

A more complex form of information that is applied to products is product information, which can take several forms and include logos, text, directions, part numbers, and other pertinent data for sellers and buyers. Product information is normally printed on the packaging of a product during product production or packaging. Inkjet printers are used for the process due to the clarity of inkjet printing.

Logos

A crucial aspect of inkjet printing is the application of product logos that have to appear on a product in a distinct and clear form such that the logo stands out and is easily identifiable. Product logos are the centerpiece of product identification and must look the same regardless of where they appear. This factor necessitates the use of inkjet printers that can create any set of colors that perfectly match the initial colors of a logo. The common four color process that is used by copiers is also used by inkjet printers to mix and blend colors to create any color of the color spectrum.

Benefits of Inkjet Printers

The wide use of the inkjet printers has given manufacturers a dependable tool for identifying and labeling their products. The speed and accuracy of the inkjet printing process make it a reliable method that requires minimal maintenance. Inkjet printers can be easily installed into any form of process since they come in a wide range of sizes and formats.

Workflow

The small amount of setup time and simple mid-production adjustments makes it possible to have a workable inkjet printer operating at full speed, quickly and efficiently. The key factors related to workflow with inkjet printers is their speed and accuracy. With single bed pass printing and low maintenance, inkjet printers can operate for hours and provide peak performance. Several technological features can be added to inkjet industrial printers to make their operation easy and convenient without the need for additional labor. In many instances, inkjet printers do not require operational oversight since they operate automatically and independently.

On-Demand Printing

A central characteristic of modern manufacturing is the need for on-demand production, which has become a constant request from industrial clients. Inkjet printers are more than capable of meeting the challenges of on-demand requirements. The inkjet printing process offers the ability to rapidly switch from one application or product to another without the need for special or unique procedures.

Quality

Of the many positive aspects of inkjet printing, the most noticeable and obvious is the quality of the images and characters that are printed by the inkjet printing process. Using multiple printing nozzles, located above a substrate, inkjet printers are able to apply concise, pristine, sharp, and clear images. The inkjet printing process has the flexibility to print small product runs or exceptionally high-volume product runs using the same technology and methods for both. This aspect of the process is what differentiates it from other types of printing processes and gives it its unique and distinguishing characteristics.

An investment in an inkjet printing system can increase the turn around times on products, radically improve the quality of printed information, and increase profitability through better product appearance and clarity. There isn’t any other printing method that can match the proclivities of the inkjet printing process.

Cost

The selection of an industrial printing process can be slightly daunting due to the expense of purchasing a system. The first most noticeable positive aspect of the process is the elimination of the need to have printing outsourced, which can be detrimental and costly. By completing printing in house, production runs, turn around times, delivery times, and efficiency all improve and are faster, a necessity in modern manufacturing. The use of an inkjet printing system makes it possible to print runs of any length without concern for having to have enough to cover the cost.

Turn Around

The use of inkjet printers makes it possible to print products as they are produced without having to wait for special or outsourced printing. This factor enhances turn around times on orders and makes it possible to quickly meet the requirements of quotas or the stipulations and requirements of customers. There are no wait times when a company has an in-house, inkjet printing system.

Conclusion

Inkjet printing systems have certain characteristics that make them a challenge to use and maintain. Although those factors are inconvenient, they are more than compensated for by the high efficiency and speed of the inkjet printing process. Production, deliveries, warehousing, and packaging work faster and more effectively when an inkjet printing system is added to industrial processing and operations.

Cardboard Tubes

Cardboard Tubes Carrying Cases

Carrying Cases Contract Packaging

Contract Packaging Corrugated Boxes

Corrugated Boxes Dot Peening Machines

Dot Peening Machines Labeling Machinery

Labeling Machinery Marking Machinery

Marking Machinery Packaging Equipment

Packaging Equipment Palletizers

Palletizers Plastic Bags

Plastic Bags Sewing Contractors

Sewing Contractors Tape Suppliers

Tape Suppliers Castings & Forgings

Castings & Forgings Bulk Material Handling

Bulk Material Handling Electrical & Electronic Components

Electrical & Electronic Components Flow Instrumentation

Flow Instrumentation Hardware

Hardware Material Handling Equipment

Material Handling Equipment Metal Cutting Services

Metal Cutting Services Metal Forming Services

Metal Forming Services Metal Suppliers

Metal Suppliers Motion Control Products

Motion Control Products Plant & Facility Equipment

Plant & Facility Equipment Plant & Facility Supplies

Plant & Facility Supplies Plastic Molding Processes

Plastic Molding Processes Pumps & Valves

Pumps & Valves Recycling Equipment

Recycling Equipment Rubber Products & Services

Rubber Products & Services