Embossing is used on paper and other materials to produce raised graphics, lettering, and designs. Embossing machines exemplify a contemporary interpretation of conventional production techniques. For example, a die set is typically used to press a complete design into the metal to create an embossed tag. In contrast, a metal tag embossing machine independently adds each character to the material using a series of striking heads. Read More…

Epilog Laser specializes in laser marking systems, CO2 lasers, diode lasers, laser cutting machines & systems for laser engraving like tabletop engravers, mid-sized engravers & large-format engraving systems. We have offered laser technology since 1988 and are the leader in CO2 & fiber laser systems.

Is your facility in need of high performance dot peen machines? Our top of the line machinery is guaranteed to meet all of your needs. We are your worry-free provider of identification systems. We will work with your team to implement our products into your business and our services are beyond compare. Our company has proven ourselves as an industry leader!

Laser Marking Technologies LLC has served the marking machinery and laser cutting services industries for over 20 years. Our years of experience and advanced technology make us a leader in marking machinery and laser-cutting services.

At Automark, our team of experts is ready and willing to tackle any of your challenging assignments. We supply marking systems for a multitude of industries such as medical, cosmetic, industrial, automotive, and more. All of our machines are manufactured to the highest quality, offered at a competitive price, and are guaranteed to last. Give us a call and a representative will speak with you...

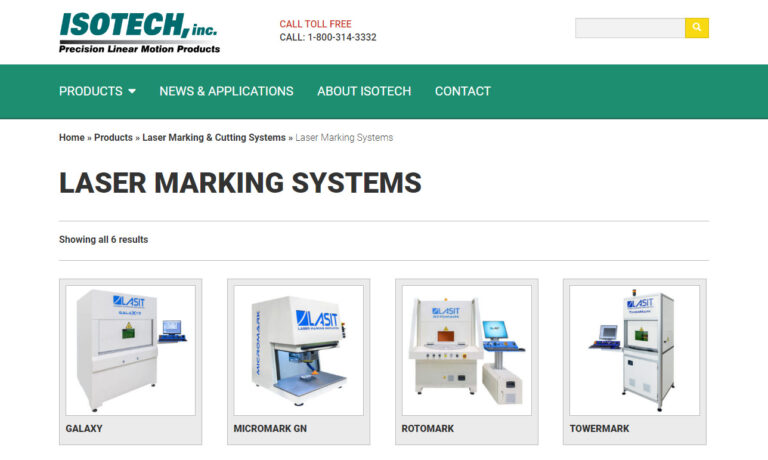

Isotech offers a full range of Fiber, C02, UV, Green, MOPA, Nanosecond, Picosecond and Femtosecond laser systems for marking, cutting and welding of many substrates. Isotech offers both standard systems as well as fully automated or custom systems depending on your specific requirements. Integrated, automated solutions with conveyors, palletized pick and place, rotary dial tables, hoppers, and...

More Embossing Machine Manufacturers

Embossing Machine Types

Embossed machines come in a wide variety of designs. Embossing machines can be portable and compact or enormous, producing tags in larger sizes or higher volumes. Additionally, they have diverse process specialties. For example, embossing devices create raised characters, but devices can indent or stamp designs.

How Embossing Machines Function

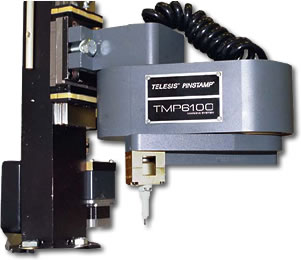

Different metal tag embossing machines operate in different ways. However, they frequently go through the same procedure. Blank metal tags are first lined up in a loader. To avoid jamming, these tags must be the proper size for the machine and as flat as feasible. The machine then takes hold of the tags and marks them once. For character embossment, one at a time, the tags are moved into the proper position. Next, the tag is pressed against each stamping head separately. Similar to a typewriter, there is one for each letter of the alphabet and the numerals 0–9. After the metal has been marked, it is finally placed in a collection bin to keep the tags organized.

Importing Information For Embossing

Embossing devices can be connected to a computer, which simplifies data entry. An excel spreadsheet is filled with the information that will be embossed. The excel file is uploaded to the computer, where the device can read it. Data organization is maintained, and modifications are more efficient.

Embossing Machine Benefits

Variable Data

Variable information presents a challenge when using standard embossing or stamping. Several designs require multiple stamps since those procedures employ a specially designed stamp for each design. For instance, 50 different stamps would need to be created if 50 different designs needed to be embossed. Not only does it take a long time to create, but it is also very expensive. This is the area where embossing machines excel. Whether or not every tag is the same doesn't matter because they mark each character uniquely. Setup times and production times remain constant. Since they are regularly employed for this function, they are frequently referred to as "variable data embossing machines."

Marking of In-House tags

Embossing machines are ideal for personalized nameplates and tags. For instance, when a consumer requests a tag with their name, an embossing machine can create a tag immediately and continue with the order. There are no manufacturing or shipment delays. Additional tag choices include multi-part tags, which make it simple to mark multiple items at once. This is also ideal when only a few tags are required each week. Ordering custom-marked tags in such small quantities would be prohibitively expensive. It saves time and money to label them internally. The blank tags for the machine are the only expense.

Quantity

In the market for metal tags, quantity is crucial. Small quantity orders aren't economical to produce using conventional production techniques. Making 20 or 30 tags would take too much time and money to create unique dies and stamps. By offering a less expensive option, embossing machines ease this restriction. In addition, smaller runs are considerably easier to control and don't need elaborate preparations.

Limitations

When embossing distinctive designs or business logos, embossing equipment cannot be utilized. They don't create original designs, typefaces, pictures, or logos. However, they can manufacture significantly more uniform tags than other methods.

There are tight limitations on size and shape. They are often made for blank tags with a rectangle form. Additionally, the blanks themselves must be as flat as possible. This is crucial since they may get stuck in the machine and cause harm to the machinery and the metal substance and halt production.

As previously stated, there are no unique designs or pictures. The fonts that can be chosen are limited, so the data has to be straightforward. Only a limited number of characters may be printed on the embossed tags. Materials may also be restricted, albeit these will differ depending on the machine. Stainless steel and aluminum are the most widely used materials. Plastic and other non-metal substrates are the focus of some machines.

Conclusion

Embossing machines fill a critical hole in metal tag marking. They successfully bridged the gap between short manufacturing runs and changeable data tags. As a result, having an on-site embossing machine makes a lot of sense for businesses that could profit from marking their nameplates.

Choosing the Correct Embossing Machine Manufacturer

To make sure you have the most beneficial outcome when purchasing Embossing Machines from an Embossing Machine Manufacturer, it is important to compare at least 5 or 6 Companies using our list of Embossing Machine manufacturers. Each Embossing Machine Company has a business profile page that highlights their areas of experience and capabilities and a contact form to directly communicate with the manufacturer for more information or request a quote. Review each Embossing Machine company website using our proprietary website previewer to get an idea of what each business specializes in, and then use our simple RFQ form to contact multiple Embossing Machine companies with the same form.

Cardboard Tubes

Cardboard Tubes Carrying Cases

Carrying Cases Contract Packaging

Contract Packaging Corrugated Boxes

Corrugated Boxes Dot Peening Machines

Dot Peening Machines Labeling Machinery

Labeling Machinery Marking Machinery

Marking Machinery Packaging Equipment

Packaging Equipment Palletizers

Palletizers Plastic Bags

Plastic Bags Sewing Contractors

Sewing Contractors Tape Suppliers

Tape Suppliers Castings & Forgings

Castings & Forgings Bulk Material Handling

Bulk Material Handling Electrical & Electronic Components

Electrical & Electronic Components Flow Instrumentation

Flow Instrumentation Hardware

Hardware Material Handling Equipment

Material Handling Equipment Metal Cutting Services

Metal Cutting Services Metal Forming Services

Metal Forming Services Metal Suppliers

Metal Suppliers Motion Control Products

Motion Control Products Plant & Facility Equipment

Plant & Facility Equipment Plant & Facility Supplies

Plant & Facility Supplies Plastic Molding Processes

Plastic Molding Processes Pumps & Valves

Pumps & Valves Recycling Equipment

Recycling Equipment Rubber Products & Services

Rubber Products & Services