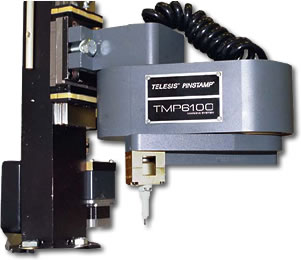

Small pins made of a rigid material, such as carbide or diamond, are used by dot peen marking machines, also known as pin stamping or pin marking machines, to indent the parts to be marked locally. Dot peen machines strike the surface with these pins, leaving minute holes that permanently modify the part’s appearance and roughness. Electrical or pneumatic power is typically used to power the dot peen process. However, only the marking process is pneumatically powered.Read More…

Epilog Laser specializes in laser marking systems, CO2 lasers, diode lasers, laser cutting machines & systems for laser engraving like tabletop engravers, mid-sized engravers & large-format engraving systems. We have offered laser technology since 1988 and are the leader in CO2 & fiber laser systems.

Is your facility in need of high performance dot peen machines? Our top of the line machinery is guaranteed to meet all of your needs. We are your worry-free provider of identification systems. We will work with your team to implement our products into your business and our services are beyond compare. Our company has proven ourselves as an industry leader!

Laser Marking Technologies LLC has served the marking machinery and laser cutting services industries for over 20 years. Our years of experience and advanced technology make us a leader in marking machinery and laser-cutting services.

At Automark, our team of experts is ready and willing to tackle any of your challenging assignments. We supply marking systems for a multitude of industries such as medical, cosmetic, industrial, automotive, and more. All of our machines are manufactured to the highest quality, offered at a competitive price, and are guaranteed to last. Give us a call and a representative will speak with you...

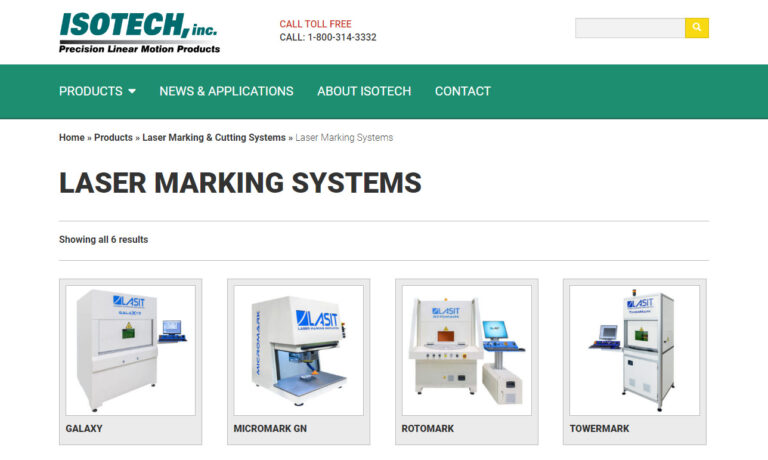

Isotech offers a full range of Fiber, C02, UV, Green, MOPA, Nanosecond, Picosecond and Femtosecond laser systems for marking, cutting and welding of many substrates. Isotech offers both standard systems as well as fully automated or custom systems depending on your specific requirements. Integrated, automated solutions with conveyors, palletized pick and place, rotary dial tables, hoppers, and...

More Dot Peen Machine Manufacturers

Complete Guide to Dot Peen Marking Machines: Types, Operation, Applications, and How to Choose the Best Manufacturer

Dot peen marking machines, also known as dot peen engravers or pin marking machines, are essential in industrial part identification, traceability, and permanent marking. These machines use a stylus or marking pin to create a series of controlled, indented dots on the surface of a component or material, forming readable alphanumeric characters, logos, 2D Data Matrix codes, and serial numbers. Dot peen technology is trusted for its durability, flexibility, and ability to engrave a wide range of materials. Whether you’re looking for an industrial dot peen marker for high-volume production lines or a portable dot peen machine for on-site metal marking, understanding how these machines work and how to choose the right equipment is critical for optimizing your marking process.

How Dot Peen Machines Work

Dot peen marking machines operate by using a hard, often carbide-tipped stylus or pin, which is actuated pneumatically or electrically to strike the surface of a part. The stylus rapidly moves along X and Y axes, controlled by precision stepper motors or servomotors, to form characters, logos, or patterns with a series of closely spaced dots. This process is sometimes referred to as micropercussion marking or pin stamping and is favored for its ability to provide permanent, tamper-proof marks on metals, plastics, and hard polymers.

The independent X and Y marking axes of a dot peen system ensure excellent mark quality and legibility, even when marking curved, uneven, or irregular surfaces. With a high resolution—often as fine as 0.025 mm—dot peen marking delivers consistent, readable results ideal for traceability and compliance with industrial standards. Users can adjust marking parameters such as dot depth, force, air pressure (for pneumatic models), character height, dot spacing, and stylus distance to achieve the desired quality and marking depth for their specific application.

Key Features of Dot Peen Marking Machines

- Permanent marking: Resistant to abrasion, heat, and chemicals; ideal for asset tracking, part identification, and regulatory compliance.

- Versatility: Mark a variety of materials, including steel, aluminum, brass, copper, hardened metals, and some plastics.

- Low operating costs: Minimal consumables and maintenance, especially with electric dot peen systems.

- High speed and automation: Suitable for integration with CNC machines, production lines, and robotic cells.

- Customizable marks: Easily program text, serial numbers, logos, or Data Matrix codes via user-friendly software.

Electric vs. Pneumatic Dot Peen Marking

Dot peen machines can be powered pneumatically (with compressed air) or electrically. Pneumatic systems offer deeper, faster marking and are suited for heavy-duty applications, while electric dot peen markers are quieter, require only a standard mains power supply, and are easier to install and operate—making them ideal for environments where compressed air is not available or desired.

Which is better for your application—electric or pneumatic dot peen?

Consider your marking depth, speed requirements, facility infrastructure, and long-term maintenance when deciding between electric and pneumatic dot peen machines. Many users prefer electric models for their simplicity and lower total cost of ownership, while industries requiring deep, high-contrast marks—such as automotive, aerospace, and oil & gas—often opt for pneumatic systems.

Types of Dot Peen Machines

Dot peen machines come in a variety of configurations to suit different industrial marking needs, part sizes, and production volumes. Explore the most common types of dot peen marking systems below to determine which is best for your application:

Portable Dot Peen Machine

Portable dot peen marking machines are designed for marking large or immobile parts that cannot be easily brought to a stationary workstation. These handheld units are ideal for on-site metal marking in industries such as shipbuilding, construction, energy, heavy equipment manufacturing, and steel fabrication. Portable dot peen markers are available in both battery-powered and mains-powered variants. Battery-powered dot peen machines provide maximum mobility and flexibility, allowing operators to mark components in the field, on the shop floor, or at remote job sites without the need for external power or compressed air.

Modern portable dot peen engravers often feature integrated touchscreens, wireless connectivity, and lightweight ergonomic designs for ease of use and operator comfort. They’re perfect for applications where parts are too large, heavy, or awkwardly shaped to fit into a benchtop marking station.

Common Use Cases for Portable Dot Peen Markers:

- Permanently marking VIN numbers, serial numbers, and batch codes on large machinery and vehicle frames

- Traceability for pipes, valves, flanges, and structural steel in oil & gas or energy industries

- Asset management and identification in warehouses or outdoor environments

- Field service or repair marking for warranty and maintenance tracking

Vibro Dot Peen Machine

The Vibro Peen marking tool—also known as a vibroengraver—creates deep, highly visible impressions in metals and hard plastics through high-frequency vibrations of the marking pin. This raised or indented mark is long-lasting and tamper-resistant, making it ideal for applications where durability is critical. Vibro dot peen technology is utilized in industries such as steel production, petrochemical, pulp and paper, and power generation. Its robust marking capability enables the marking of hard, coated, or rough surfaces that may challenge other marking methods.

Typical Applications for Vibro Dot Peen Marking:

- Permanently branding metal products for traceability and anti-counterfeiting

- Adding quality assurance marks or inspection stamps to metals and alloys

- Marking grade, heat number, or purity on metal tubes, pipes, and sheets

- Industrial part identification in harsh or corrosive environments

Vibro dot peen marking systems are valued for their rugged construction, consistent results, and ability to mark a wide range of materials, including stainless steel, carbon steel, aluminum, copper, and even some engineering plastics.

Integrated Dot Peen Machine

Integrated dot peen marking systems are specially engineered for seamless integration into automated production lines, robotic cells, or custom marking stations. These systems are popular among OEMs, system integrators, and industrial automation specialists who need to incorporate reliable, repeatable part marking into manufacturing workflows. Integrated dot peen machines feature advanced control interfaces—such as PLC connectivity, Ethernet/IP, and fieldbus support—to communicate with other automation or MES systems, ensuring smooth data exchange and traceability compliance.

Integration-ready dot peen markers are compact, modular, and highly configurable. They support automated part handling, fixture positioning, and in-line verification, making them the go-to choice for high-throughput industries such as automotive, aerospace, electronics, and medical device manufacturing.

Benefits of Integrated Dot Peen Marking:

- Streamlined automation and reduced manual labor

- Real-time data integration for part tracking and quality management

- Consistent, repeatable marks for regulatory and supply chain requirements

- Reduced marking errors and improved production efficiency

Benchtop Dot Peen Machine

Benchtop dot peen marking machines—sometimes called desktop dot peen engravers—are the workhorses of industrial marking. Mounted on a stable workbench or workstation, they are designed for marking small to medium-sized parts with high precision and accuracy. Benchtop systems offer greater control over the marking process, making them ideal for applications requiring fine detail, close tolerances, or repeatable positioning.

Parts to be marked are typically secured in a fixture or vice, ensuring consistent placement and orientation. Many benchtop dot peen machines are equipped with motorized Z-axes for automatic height adjustment, programmable marking fields, and user-friendly software for designing and storing marking patterns. These systems are widely used in automotive, aerospace, medical device, electronics, and tool manufacturing industries.

Questions to Consider When Choosing a Benchtop Dot Peen Engraver:

- What is the maximum part size and weight the machine can accommodate?

- Does the system support automatic serialization or barcode marking?

- Is the software intuitive and compatible with your existing workflow?

- How easy is it to change fixtures or marking programs for different jobs?

Double Nose Engraving Machine

Double nose dot peen engraving machines are advanced systems featuring two interchangeable stylus heads, enabling rapid tool changes and high-speed marking. This dual-head design increases throughput and allows for intricate, complex designs on flat surfaces, making it perfect for decorative marking, custom engraving, and high-volume part serialization. The double nose configuration enhances marking flexibility and reduces downtime for tool changes—crucial for demanding production environments.

These machines are particularly well-suited for marking metals, alloys, and hard plastics in industries such as jewelry manufacturing, electronics, and precision engineering. With improved performance and precision, double nose dot peen engravers are a top choice for applications requiring both speed and detail.

Advantages of Dot Peen Machines

Why choose dot peen marking for your industrial identification and traceability needs? Explore the benefits below:

- Durable, permanent marks: Resistant to wear, corrosion, and tampering—crucial for compliance and warranty tracking.

- High-speed marking: Efficient for both manual and automated operations, reducing bottlenecks in production lines.

- Cost-effective solution: Minimal consumables and low maintenance, especially with electric dot peen markers.

- Versatility: Capable of marking a wide variety of shapes, sizes, and materials.

- Portability: Portable models allow for flexibility in marking location and part handling.

- Automation-friendly: Easily integrated into automated manufacturing processes, with data connectivity for traceability.

- Adjustable mark quality: Customizable depth, size, and resolution to meet application-specific requirements.

- Low environmental impact: No inks, chemicals, or consumables required, making dot peen an eco-friendly marking technology.

Disadvantages of Dot Peen Machines

While dot peen marking offers many benefits, it’s important to consider its limitations before making a purchasing decision:

- Noise: The process can be loud, especially with pneumatic systems, and may require sound enclosures or hearing protection.

- Surface requirements: Best suited for metals and rigid materials; not ideal for marking soft plastics, thin films, or flexible materials.

- Fixture requirements: Parts must be securely fixed or supported to ensure legible, accurate marks.

- Wear and maintenance: Stylus pins, especially carbide tips, can wear out and require periodic replacement.

- Marking speed: While generally fast, dot peen marking is slower than some laser or inkjet marking technologies for certain applications.

- Barcode limitations: Traditional dot peen may struggle with high-density 2D codes or very small barcodes, though some advanced systems can mark Data Matrix codes.

Key Applications and Industries for Dot Peen Marking

Dot peen marking technology is trusted by a wide range of industries for its reliability and permanent marking capabilities. Typical applications include:

- Automotive: VIN marking, engine and chassis identification, component serialization, and quality assurance tracking.

- Aerospace: Part traceability, MRO (maintenance, repair, and overhaul) marking, and compliance with aerospace standards.

- Steel and Metal Fabrication: Marking pipes, beams, flanges, and sheet metal for traceability and inventory management.

- Oil & Gas: Asset identification for pipes, valves, and equipment in harsh environments.

- Medical Device Manufacturing: UDI (Unique Device Identification) marking for regulatory compliance.

- Electronics: PCB serialization, traceability, and anti-counterfeiting.

- Tool and Die: Marking tools, molds, and dies with part numbers, logos, or calibration data.

- Defense and Security: Marking weapons, munitions, and critical components with serial numbers and batch codes.

Looking for a specific dot peen marking solution?

Contact our experts for a tailored recommendation based on your industry, part material, and marking requirements.

How to Choose the Best Dot Peen Marking Machine for Your Needs

Selecting the right dot peen marking machine involves evaluating several critical factors to ensure optimal performance, reliability, and return on investment. Consider the following buyer-intent questions to guide your search:

- What materials and part sizes will you be marking most frequently?

- Do you require a portable, benchtop, or integrated solution for your workflow?

- What marking depth, quality, and speed are necessary for your application?

- Does your facility have access to compressed air (for pneumatic systems) or is electric operation preferred?

- Is software integration or data connectivity (e.g., ERP/MES, barcode scanners) required?

- What is your budget, and what is the expected total cost of ownership?

- Are there specific industry standards or regulatory requirements your marks must meet?

By answering these questions, you can narrow down your options and select the best dot peen marker for your unique production environment.

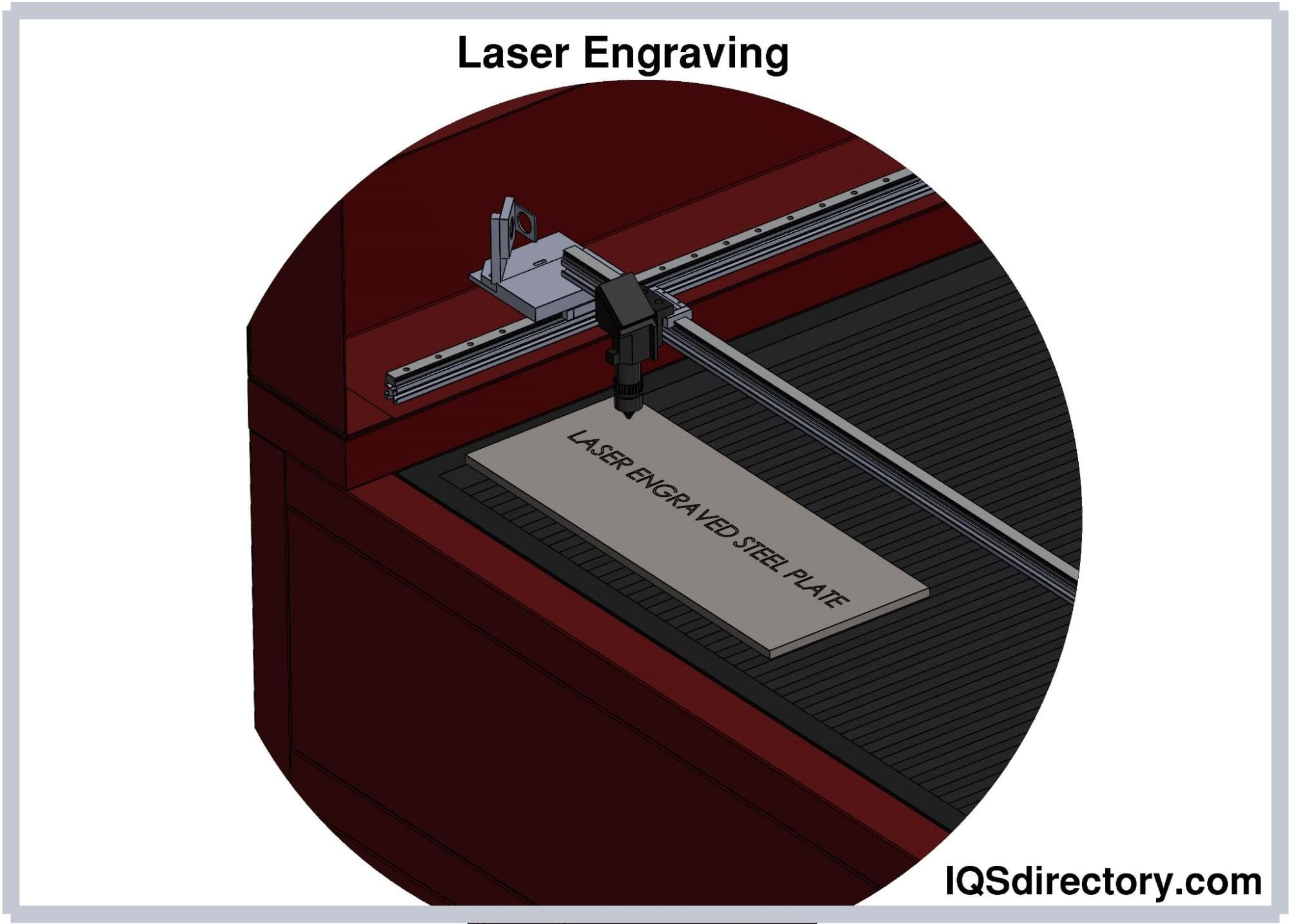

Comparing Dot Peen Marking to Other Industrial Marking Technologies

Dot peen marking stands out for its permanence, versatility, and cost-effectiveness, but how does it compare to other marking solutions such as laser marking, inkjet printing, or electrochemical etching?

- Laser marking is ideal for ultra-fast, high-resolution, and contactless marking, but it requires a larger investment and may not be as effective on rough or coated surfaces.

- Inkjet marking is suitable for non-permanent, high-speed coding on packaging and products, but lacks the durability of dot peen.

- Electrochemical etching works well for marking conductive metals with fine detail, but is best for flat surfaces and requires consumables.

For applications requiring permanent, tamper-proof, and cost-effective part marking, dot peen remains an industry leader.

Choosing the Proper Dot Peen Machines Manufacturer

To ensure the most productive outcome when purchasing dot peen marking equipment, it’s essential to compare offerings from multiple dot peen machine manufacturers and suppliers. Use our comprehensive list of dot peen marking machine providers to:

- Review detailed business profiles highlighting experience, capabilities, and support services

- Compare product portfolios, machine features, and customer testimonials

- Request quotes directly using our standardized RFQ form for pricing and lead time information

- Preview manufacturers’ websites and digital catalogs to assess specialization and technology leadership

- Contact technical experts to discuss your marking requirements, integration needs, and after-sales support

Evaluating at least 4 or 5 dot peen machine manufacturers allows you to make an informed decision based on quality, reliability, price, and service. Look for suppliers who offer robust warranties, responsive technical support, and proven installation and training programs to maximize your investment.

Ready to source your dot peen marking solution?

Use our marking tools directory to connect with leading dot peen machine manufacturers and request a personalized quote tailored to your application.

Frequently Asked Questions About Dot Peen Marking Machines

- What maintenance is required for dot peen marking machines? Regular inspection and replacement of the stylus or marking pin, cleaning of the marking head, and periodic calibration ensure optimal performance and mark quality.

- Can dot peen systems mark 2D Data Matrix or QR codes? Many advanced dot peen machines can mark 2D codes, though resolution and readability depend on pin size and material hardness.

- Is dot peen marking suitable for delicate or coated surfaces? Dot peen is best for robust materials; for delicate coatings or thin surfaces, consider laser or inkjet marking solutions.

- How deep can a dot peen marker engrave? Marking depth depends on machine type, material hardness, and pin force, but can range from microns up to 1mm or more in soft metals.

- What file formats do dot peen machines support? Most systems accept standard vector and text file formats; consult your manufacturer for compatibility details.

Get Expert Guidance on Dot Peen Marking Solutions

Still have questions about selecting, implementing, or maintaining dot peen marking equipment? Contact our marking specialists for tailored advice, product recommendations, and to request free samples or demos of leading dot peen marking machines. Optimize your part marking process today with high-performance, reliable dot peen technology.

Explore more about industrial marking systems, including laser marking machines and industrial marking tools

Cardboard Tubes

Cardboard Tubes Carrying Cases

Carrying Cases Contract Packaging

Contract Packaging Corrugated Boxes

Corrugated Boxes Dot Peening Machines

Dot Peening Machines Labeling Machinery

Labeling Machinery Marking Machinery

Marking Machinery Packaging Equipment

Packaging Equipment Palletizers

Palletizers Plastic Bags

Plastic Bags Sewing Contractors

Sewing Contractors Tape Suppliers

Tape Suppliers Castings & Forgings

Castings & Forgings Bulk Material Handling

Bulk Material Handling Electrical & Electronic Components

Electrical & Electronic Components Flow Instrumentation

Flow Instrumentation Hardware

Hardware Material Handling Equipment

Material Handling Equipment Metal Cutting Services

Metal Cutting Services Metal Forming Services

Metal Forming Services Metal Suppliers

Metal Suppliers Motion Control Products

Motion Control Products Plant & Facility Equipment

Plant & Facility Equipment Plant & Facility Supplies

Plant & Facility Supplies Plastic Molding Processes

Plastic Molding Processes Pumps & Valves

Pumps & Valves Recycling Equipment

Recycling Equipment Rubber Products & Services

Rubber Products & Services